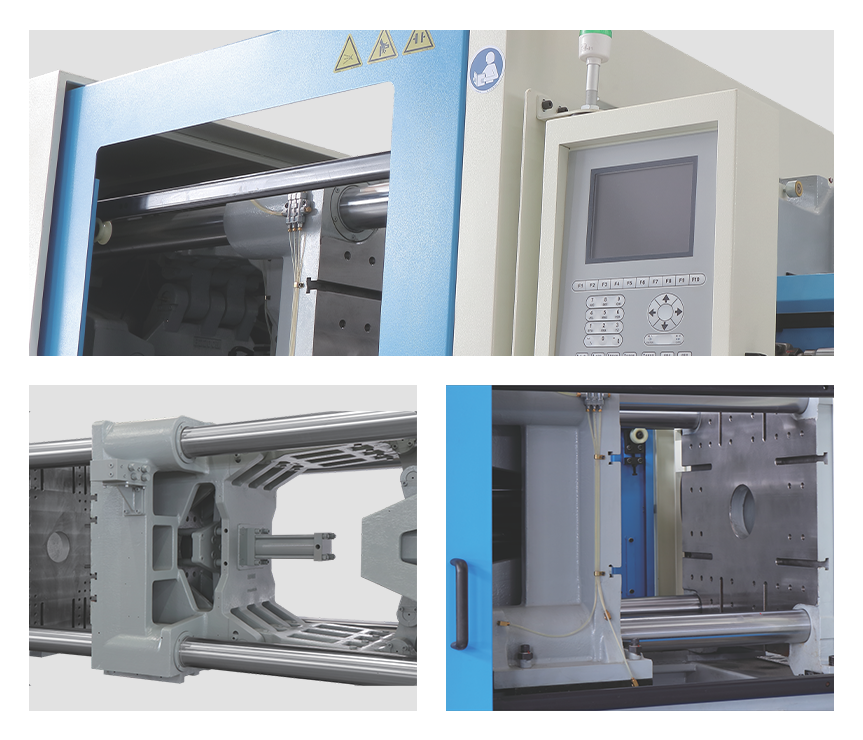

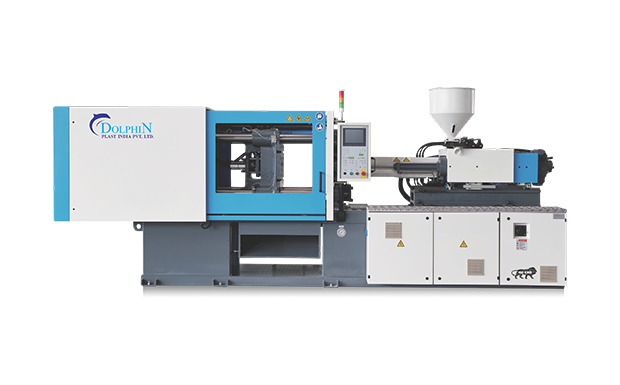

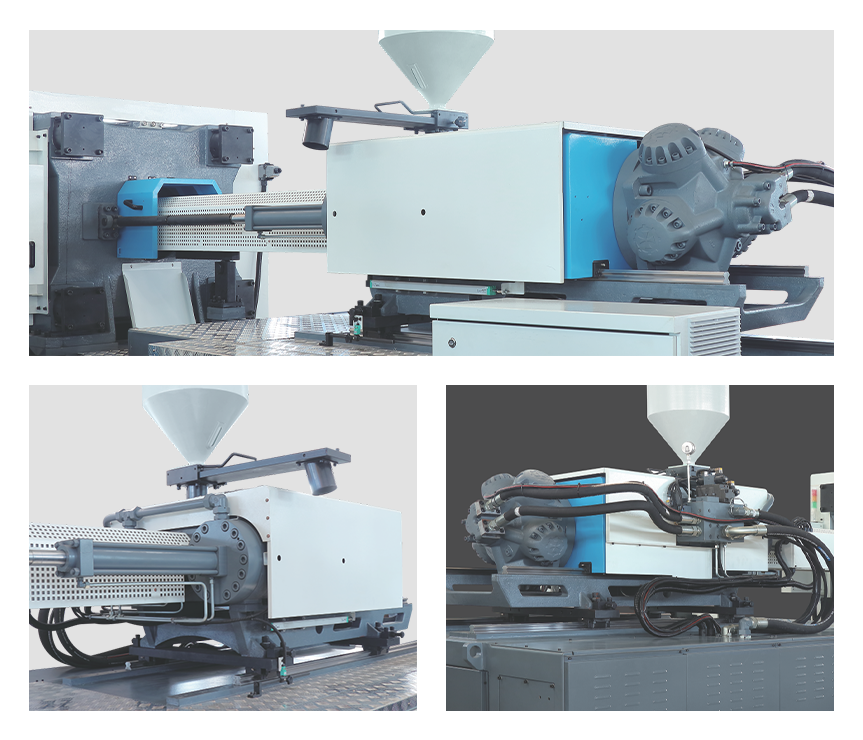

CLAMPING UNIT

Large Open Distance And High Rigidity Clamping Unit

- Longer and wider guide support, higher repeat accuracy. improving molded product quality and molds lifespan largely

- The overall mechenical rigidity far exceeds that of other suppliers, which not only improves the service life of the machine, but also effectively protects the mold.

- Larger space between tie bar, adaptable to more sizes of molds and multi-cavity demands.

- European-style ejector structure, larger space, more conve-nient maintenance.

- Key guiding pa rts for the bar, ejectors are upgraded with graphite copper bushes. And self-lubricating alloy sliding plate are used on the movable platen and rear platen Mold opening and locking is fast and precise.

- The mechanical structure and connecting rod design are more optimized, the running speed is faster, more stable, and the efficiency is improved.